This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

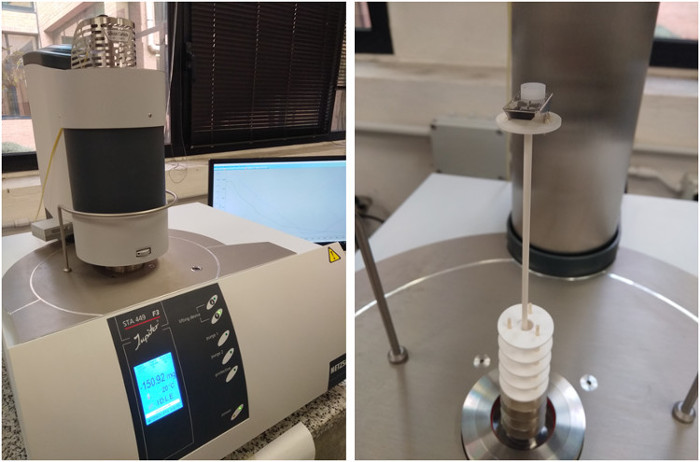

Simultaneous Thermal Analyzer TG-DSC

Supervisor : Elisa Mercadelli

The thermal analyses are the set of techniques in which a physical property of a substance is measured as a function of temperature (or time) while the sample is subjected to a controlled temperature program (heating, cooling, isotherm).

In the Thermogravimetric Analysis (TGA) the mass of a sample is measured as a function of temperature or time, while the Differential Scanning Calorimetry (DSC) measures the difference in the amount of heat required to increase the temperature of a sample and reference as a function of temperature.

The Simultaneous Thermal Analysis (STA) allows to measure simultaneously (on the same sample and in the same

analytical conditions) mass and calorimetric variations.

The analyses are performed following the GLP (Good Laboratory Practice) principles. The maximum working temperature is 1600°C, depending on material, analysis conditions and technique (measuring head) used.

Some application examples:

• Recording of chemical-physical transformations of the material during the heat treatment.

• Studies of oxidation resistance, reactivity, solid state synthesis, sintering, also as a function of the working atmosphere.

• Evaluation of decomposition processes, i.e. decarbonation, debonding, etc.

• Quantitative composition information of the analyzed material.

• Evaluation of reaction enthalpies and specific heat.

• Studies of kinetics and reaction mechanisms.

STA 449 F3 Jupiter, Netzsch Geraetebau

• SiC Furnace.

• Temperatures range: RT – 1600°C.

• Heating rate: 0.001 – 50°C/min.

• Type S thermocouple.

• TG resolution: 0.1 μg.

• DSC resolution: ± 2%.

• Gas flux: air, N2, Ar, CO2.