Innovative solution for the preservation of cultural heritage – Geopolymers

Lightweight and colored geopolymeric materials

Principal Investigator: Sabrina Gualtieri

Personnel involved: Michele Macchiarola, Mauro Mazzocchi

The activity deals with the development of eco-compatible materials and ecofriendly technologies able to take care the cultural heritage in terms of a scarce invasive approach and respect of the materials.

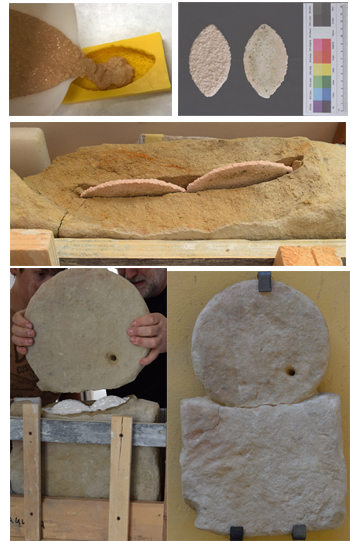

Lightweight mobile supports and layered shells made of geopolymers for replacing fragments of detached mosaics; colored geopolymeric tesserae for mosaic integration; pivots of geopolymeric composites to be used in the re-assembling of fractured artworks.

Inorganic raw materials are used in order to formulate opportune mix designs reproducing, from the chemical-physical point of view, the components of the ceramics or mosaics artworks. The inorganic nature of the raw materials guarantees high compatibility with the artwork and the working process at very low temperatures is sustainable for the environment.

The versatility of geopolymeric materials, the possibility to put inside natural and artificial aggregates as well natural, synthetic or steel-fibers, and to color them let to design tailored interventions. The addition of inerts different in dimensions and physical characteristics, allows to define specific mix-design able to guarantee very similar textures to the materials to be preserved.

According to the final target, the introduction of suitable aggregates/reinforcements can impove the mechanical performances and modify the design, the dimension and the distribution of the pores.

By using specific organic agents, it is possible to vary the workability of the geopolymeric mixture that is a basic parameter in the preservation and restoration interventions.

Equipment & Processes

The synthesis of these materials is at room temperature by a geopolymerization reaction between an aluminum-silicate reactive material and a high alkaline solution (pH 12). Their hardening and solidification can be also happen at room temperature and in short time according the dimensions of the final piece (usually 28 days can be sufficient).

The drying is a fundamental step in the working process; it has to be slow and it must to be checked in order to avoid or at least to minimize the formation of internal cracks that can compromise the integrity not only of the few pieces but also of the artwork.

It has been realised:

- Multi-layered reinforced mobile supports for the replacement of detached mosaic fragments previous bedding on concrete layers;

- Layered shell made of two different geopolymeric composites reinforced with a steel-net hosting a Roman mosaic fragments and able to preserve it when exposed outdoor.

- Gepolymeric pivots used as anchorage elements for reassemblying broken artistic slab lastre or funerary stele.

Examples of application of geopolymeric composites: reassembling of sandstone votive stele by using geopolymeric pivots. The votive stele is exposed in the court of Museo Archeologico in Bologna

Main Collaborations

• Accademia Belle Arti Bologna

• Soprintendenza Archeologica della Toscana

• Bologna University, Department of Chemistry “Giacomo Ciamician”

• Bologna University, Department of Physics and Astronomy – DIFA

• CertiMac Scral

Projects

• Mitai Linea 4