Biomimetic hydroxyapatite for hard connective tissues

Ceramic nanoparticles and porous scaffolds

Principal investigators: Anna Tampieri, Simone Sprio

Personnel involved: Monica Sandri, Silvia Panseri, Monica Montesi, Massimiliano Dapporto, Marta Tavoni

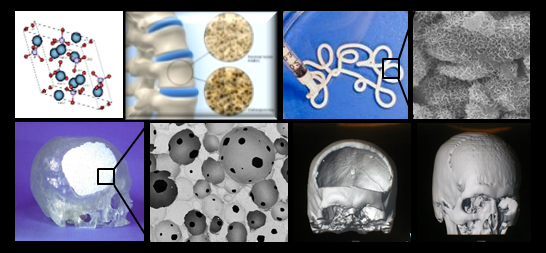

Hydroxyapatite (HA) is the elective material for bio-devices addressed to bone regeneration. However, in its stoichiometric form HA has poor bioactivity and bio-resorbability, whereas biologic apatite is characterized by nanocrystallinity and multiple ion doping conferring specific biologic functions.

In this respect, ISSMC has deep expertise in the development of nanocrystalline apatites presenting multiple foreign ions replacing calcium and/or phosphate, e.g.: Mg2+, CO32-, Na+, K+, SiO44-, Sr2+, Ga3+, Zn2+. Such substitutions confer enhanced bio-resorbability and the ability of delivering instructive signals for cells, i.e. to promote new bone formation, or to give enhanced antibacterial effect.

Biomimetic apatites can be obtained in the form of nanopowders that can be processed into highly bioactive granulates as bone fillers. Moreover, apatite powders can be processed to obtain consolidated bodies functioning as ceramic targets for physical deposition technologies, addressed to the development of bioactive coatings.

Biomimetic apatites are also the base of 3-D ceramic scaffolds for regeneration of extensive bone defects, particularly in orthopedics and cranio-maxillofacial surgery. The scaffolds can be obtained by several forming processes, such as replica, direct foaming, or freeze casting, which are methods based on the development of ceramic slurries with optimized rheological properties and controlled sintering processes.

The scaffolds are designed to show high bioactivity and osseointegrability, thanks to the chemical composition mimicking the bone mineral, and the presence of open and interconnected porosity, which induces and stimulates the penetration of new bone, vascularization and recovery of adequate biomechanical performance. These properties are particularly desired in cranial and maxillofacial surgery where our scaffolds have already found application in the clinic with a hydroxyapatite bone substitute considered the material of choice also because it is the only one applicable in children.

In order to obtain superior mechanical properties enabling the application of our scaffolds in maxillofacial surgery, as regions characterized by high mechanical stress, reinforced bioactive ceramics are under study thanks to the use of composites of calcium-phosphate matrices with nano / bioactive reinforcement microstructures. Mechanical reinforcement mechanisms driven by appropriate modulation of ionic doping in apatites are also being studied. It has recently been found that the alteration of the crystalline structure induced by ionic doping induces changes in the final composition and in the microstructure, following thermal consolidation, by which it is possible to modulate fracture resistance, bioactivity and antimicrobial abilities. To obtain a greater bio-stimulation ability in vivo, the scaffold can be obtained with magnetic properties by compositing with magnetic ceramic phases and sintering under controlled atmosphere to avoid the degradation of the magnetic properties.

Furthermore, the porous ceramic scaffolds can be functionalized by blending with natural or bio-erodible polymers to enhance fracture strength and tailor elastic properties towards those typical of bones. The cross-linking with biocompatible chemical agents allows to tailor the bio-degradation profile and to incorporate bioactive molecules like drugs and grow factors, which can thus be released with controlled kinetics.

The long-lasting collaborations with companies active in the biomedical field is a strong driver for the development of new biomaterials and devices for solving clinical needs of relevant socio-economic impact. In particular, the collaboration with Finceramica S.p.A., as partner of many EU-funded research and national projects (e.g.: AUTOBONE, OPHIS, MAGISTER, Bioprotesi, Ageing) led to the development of an international patent protecting ion-substituted biomimetic apatites, and several commercial products.

Equipment and processes

Equipment

- Incubator

- Furnaces for debonding

- Furnaces operating in air atmosphere

- Freeze drier

- Mixers

- 3D printing equipment

Processes

Technologies used to develop ion-doped hydroxyapatite powders

- Chemical synthesis

- Sintering processes

Technologies used to develop large 3-D porous scaffolds

- Chemical synthesis

- Powder processing

- Replica by sacrificial templates

- Direct foaming

- Freeze casting

- Sintering processes

Technologies used to develop bioactive injectable pastes

- Solid state reactions

- Chemical synthesis

- Powder processing

Main collaborations

- University of Trento

- Finceramica S.p.A.

- Istituti Ortopedici Rizzoli

- University of Toulouse

- University Friedrich Schiller of Jena

- University of Brighton