Multifunctional ceramic composites

Ceramic-ceramic and ceramic-metal composites

Principal investigators: Diletta Sciti, Valentina Medri, Frédéric Monteverde

Personale coinvolto: Laura Silvestroni, Luca Zoli, Cesare Melandri, Claudio Capiani, Andreana Piancastelli

The development of electrically conductive ceramic composites with good high-temperature structural properties is of great interest for a wide range of applications. Composites made of insulating ceramics (such as alumina, silicon nitride, aluminium nitride, silicon carbide ) and variable amounts of electro-conductive phases (metallic, intermetallic or ceramic) can fulfil these requirements.

The following composites are produced and studied at ISSMC:

- Si3N4-TiN, Si3N4-MoSi2

- AlN-SiC-MoSi2, AlN-SiC-ZrB2, AlN-SiC-ZrC

- Al2O3-TiC, Al2O3-TiB2, Al2O3-TiN, Al2O3-Mo, Al2O3-NiAl.

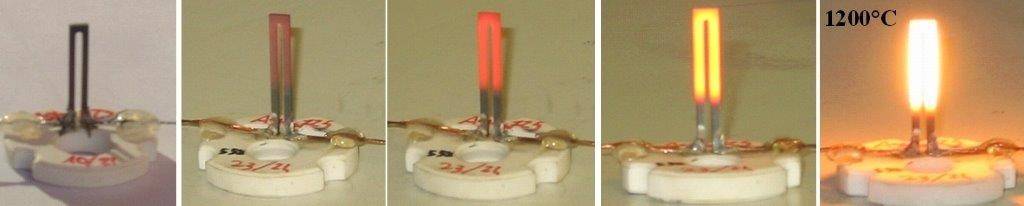

These composites are currently employed in applications as heaters or igniters. The addition of a “lubricant” secondary phase such as h-BN allows for high machinability. Cermets (ceramic-metal composites) based on TiCN-WC-Ni-Co and WC-Co hard metals are also studied as cutting tools. In this regard, the POR-FESR HI-Score project aims at the reduction of energy consumption during machining, the replacement of cutting oils with cryogenic fluids and the study of ceramic materials for cutting tools. Characteristics like

- sintering behaviour

- microstructure

- electrical resistivity

- thermo-mechanical properties at room and high temperature

are investigated.

Equipment and processes

- Hot pressing furnace

- Controlled atmosphere furnaces (Tmax: 2400°C)

- Tribometer

- Microhardness indenter

- Nanoindenter

- Universal machines for mechanical testing (Tmax: 1500°C)

Main collaboration

- Consorzio MUSP- Macchine Utensili e Sistemi di Produzione

- Piacenza, Italia

- Instituto de Ciencia de Materiales de Sevilla

- Centro Mixto CSIC-US, Sevilla, Spain

Projects

Publications & Patents

- Chicardi, F.J. Gotor, V. Medri, S. Guicciardi, S. Lascano, J.M. Córdoba, Hot-Pressing of (Ti, Mt)(C, N)-Co-Mo2C (Mt=Ta, Nb) powdered cermets synthesized by a mechanically induced self-sustaining reaction, Chemical Engineering Journal 292 (2016) 51–61.

- Chicardi, Y. Torres, M.J. Sayagués, V. Medri, C. Melandri, J.M. Córdoba, F.J. Gotor, Toughening of complete solid solution cermets by graphite addition, Chemical Engineering Journal 267 (2015) 297–305.

- J. Gotor, R. Bermejo, J.M. Córdoba, E. Chicardi, V. Medri, D. Dalle Fabbriche, Y. Torres, Processing and characterisation of cermet/hardmetal laminates with strong interfaces, Materials and Design 58 (2014) 226–233.

- J. M. Córdoba, E. Chicardi, R. Poyato, F. J. Gotor, V. Medri, S. Guicciardi, C. Melandri, Spark plasma sintering of TixTa1_xC0.5N0.5-based cermets: Effects of processing conditions on chemistry, microstructure and mechanical properties, Chemical Engineering Journal 230 (2013) 558–566.