This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

MEASURED

MEmbrAne Scale Up foR chEmical inDustries

Principal Investigator: Mariarosa Raimondo

Involved personnel: Alessandro Corozzi, Guia Guarini, Maria Caruso

Starting Date: 01/01/2023

Duration: 48 months

Total Funding: 7’971’409 €

Grant Agreement No.: 101091887

Call: HORIZON-CL4-2022-RESILIENCE-01-14

Topic: Membranes for gas separations – membrane distillation

Coordinator: Fausto Gallucci Eindhoven University of Technology (TU/E)

Consortium: The interdisciplinary MEASURED consortium is composed by 17 participants – 2 SMEs, 7 industries and 8 Universities/research centers

Official website: www.measured-project.eu

THE PROJECT

The project MEASURED aims at developing and demonstrating advanced membrane materials for Pervaporation (PV), Membrane Distillation (MD) and Gas Separation (GS) technologies applied to acrylic ester production, membrane manufacturing and gas separation from a carbon capture & utilization (CCU) stream. PV targets 1 m2 of membrane processing H2O flux > 1.0 kg/m2·hr using a 55-channel tube in the industrial setting of ARKEMA, a stability > 90% over 3 months of testing, resulting in a CAPEX 30% lower compared to current cost – from 2100 €/m2 to 1500 €/m2. MD aims at treating the daily amount of generated wastewater (70 L/h) from the manufacturing facility of PVDF membranes at GVS Spa with energy supply via about 100 Solar/Photovoltaic collectors, showing higher chemical resistance (> 10%), >25% reduction of water footprint, permeability of reused MD for Microfiltration > 500 L/m2·hr·bar. GS prototype will be scaled-up to a membrane area of 1.2 m2/module using a 61-channel tube installed downstream the GAYA methanation unit of Engie, reducing the membrane cost (produced at large scale) from 1944 €/m2 to 795 €/m2 (almost 60%). At the end of the project, the integrated MEASURED technologies will reach a TRL7 demonstration over 20,000 hours operation under (industrial) operational conditions. MEASURED includes a thorough multiscale modelling and simulation techniques including a full Life Cycle Assessment and addresses the societal implications to increase the acceptance and further market readiness.

WORKPLAN

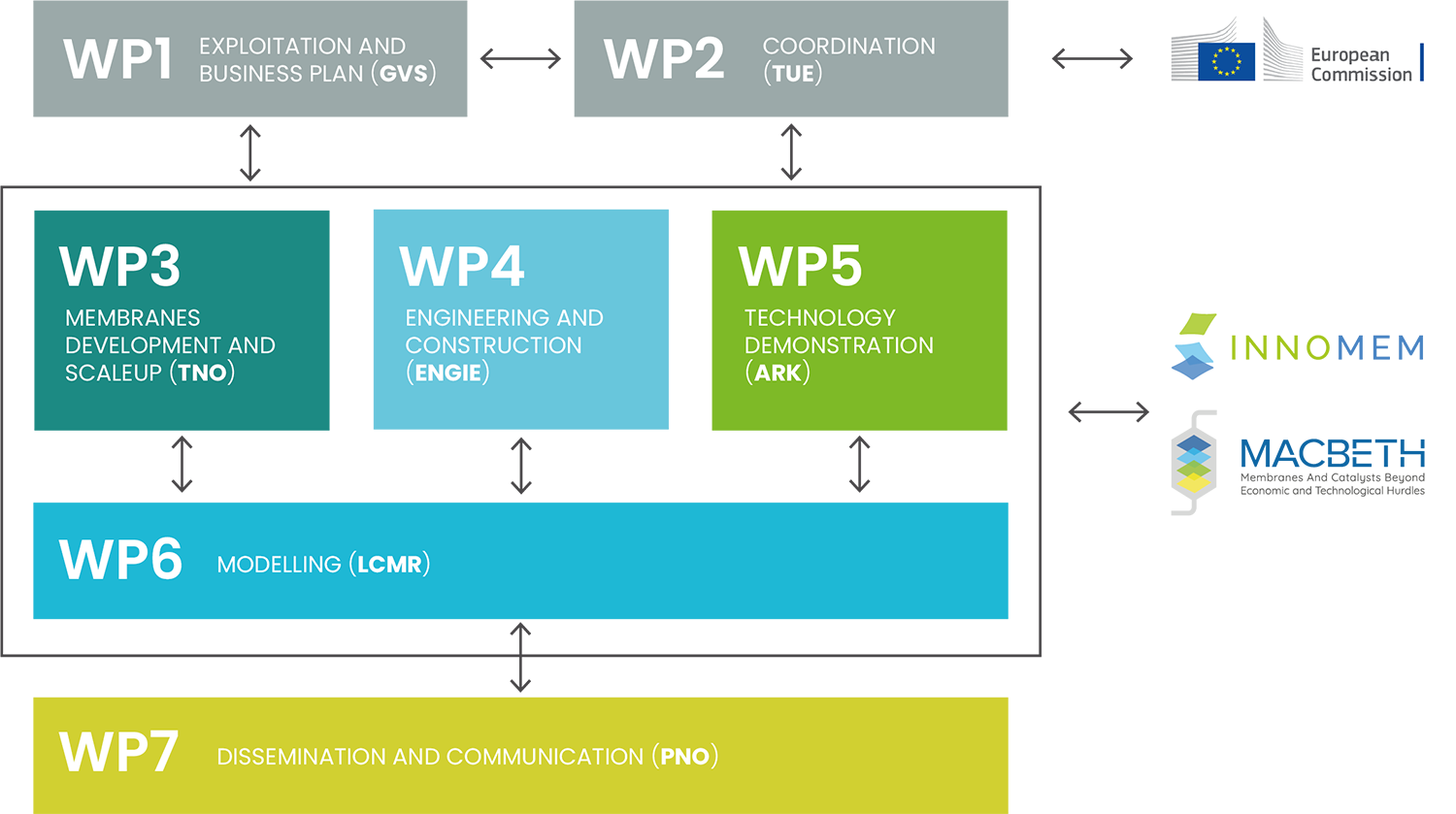

The project work plan identifies and organizes the logical phases of the implementation of the project and includes consortium management, assessment of progress and results, as well as dissemination and exploitation of results. The overall strategy of the work plan is designed to carry out detailed investigations into the scientific topics identified as necessary to bring the concept beyond state of the art and reach the expected innovation objectives. To achieve the objectives in an efficient way, MEASURED has been divided into 7 work packages:

AIMS & TARGETS

MEASURED’s main objective is to provide a quantum leap in the development of membrane technologies for pervaporation, gas separation and membrane distillation, setting the basis for future commercialization of greener technological pathways all along the value chain. This goal will be reached by:

- Designing and setting up a broad and complete network of value chains with world-class industrial partners, universities, research centres to develop the key building blocks for membrane applications. MEASURED will connect material developers with key players in the chemical industry, thereby matching existing needs and new products with the essential link provided by innovative organisations that are capable of developing advanced membrane technologies that will meet the challenges of the coming years.

- Developing a set of flexible cost-effective and environmentally friendly membranes that can be easily tailored for different applications (cross-fertilization).

- Laying the foundations for new business opportunities, including:

- The development of novel ceramic, carbon molecular sieve (CMSM) and polymeric membranes for their integration in newly designed membrane modules for three applications.

- The development of 3 new prototypes for the testing of the membranes in different applications at TRL7.

- The creation of a spinoff company for the commercialization of CMSM for different applications.

Partners

- Eindhoven University of Technology (TU/E) – Netherland

- Fundación TECNALIA Research & Innovation (TECNALIA) – Spain

- Nederlandse Orrganisatie Voor Toegepast Natuutwetenschappelijk Onderzoek TNO (TNO) Netherland

- The National Institute of Chemistry (NIC) Slovenia

- Università della Calabria (UNICAL) Italy

- Rauschert Kloster Veilsdorf GMBH (RAUSCHERT) Germany

- Consiglio Nazianale delle Ricerche (CNR) Italy:

- GVS Group (GVS) Italy

- Engie (ENGIE) France

- Arkema France SA (ARKEMA) France

- Orelis Environment SAS (OE) France

- Ciaotech (PNO GROUP) Italy

- MODELTA BV (LCMR) Netherland

- Ceramiques Techniques et Industrielles (CTI) France

- Aix-Marseille University (AMU) France

- Fundacio Eurecat (EURECAT) Spain

- Circular Water Technologies (CWT) Sweden