This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

T-SC

Transparent spinel ceramic

Principal investigator: Valentina Biasini

Involved personnel: Jan Hostaša, Andreana Piancastelli, Laura Esposito

Starting date: 23/01/2017

Duration: 18 months

Total funding: 500 000 € (CNR-ISTEC: 250 000 €)

Action: Project contract n. 2016/02 between the Ministry of Defence of Italy and the the Ministry of Defense of the government of Israel

Coordinator: CNR-ISTEC

Consortium: CNR-ISTEC and ICSI, The Israel Ceramic and Silicate Institute, Haifa, Israel

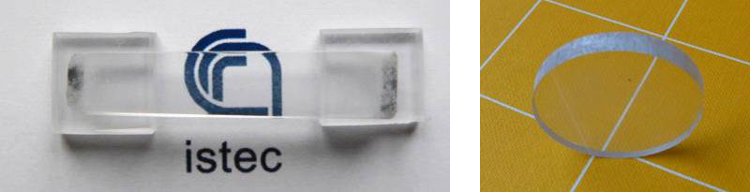

T-SC focusses on the development of a ceramic technology for the production of ceramic-based spinel (MgAl2O4) with a wide transparency range from the near UV to the mid IR.

Transparent polycrystalline ceramics have high chemical and thermo-mechanical properties and find applications as protective armor windows under harsh conditions, as a protection for electro-optical sensors, as next-generation spacecraft windows and as laser hosts.

Magnesium aluminate spinel has a cubic crystal structure and is therefore optically isotropic. In addition to a high melting point, it has excellent mechanical properties, outstanding hardness and a superb transparency from the near UV down to the mid IR range, it remains transparent beyond the limit for g-AlON (aluminum oxynitride), the direct transparent competitor, which is set at 4-4.5 μm; it also has a lower specific weight than the oxynitride.

Unfortunately, despite the consistent research worldwide at the laboratory scale level and the considerable amount of money invested, only few companies commercialize spinel-based components at the moment, all of them through a production process based on the sintering up to full density of MgAl2O nanopowders, using high-priced equipment providing very high pressure (up to 6 GPa) coupled with a high temperature treatment.

In this respect, the scope of the research is the development of an industrial friendly technology for the production of spinel-based transparent plates requiring lower cost raw materials and equipment.

The targeted technology involves the use of separated Al2O3 and MgO powders instead of already synthesized spinel powders. This method promotes the densification via reactive sintering, fastens the densification process by lowering the sintering temperature and as a result decreases the pressure required during hot pressing. As a result, pressure and temperature processing conditions needed for the production would be compatible with the use of low or medium priced equipment.

Pubblicazioni e brevetti:

- L. Esposito, A. Piancastelli, P. Miceli, S. Martelli. A thermodynamic approach to obtaining transparent spinel (MgAl2O4) by hot pressing. Journal of the European Ceramic Society, 35 (2015) 651-561

- L. Esposito, A. Piancastelli and S. Martelli. Production and characterization of transparent MgAl2O4 prepared by hot pressing. Journal of the European Ceramic Society, 33 (2013) 737–747