This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

SLIPS

SLIPS: Slippery surfaces for drag reduction

Principal Investigator: Dott.ssa Mariarosa Raimondo

Involved Personnel: Dott.ssa Federica Mancini, Dott. Massimiliano Dapporto

Start Date: 30/11/2023

Duration: 24 months

Total Funding: 239 970,40 € (CUP D53D23018190001)

Call: PIANO NAZIONALE DI RIPRESA E RESILIENZA (PNRR) Missione 4 “Istruzione e Ricerca” – Componente C2 Investimento 1.1, “Fondo per il Programma Nazionale di Ricerca e Progetti di Rilevante Interesse Nazionale (PRIN)” PRIN 2022 PNRR

Role of CNR-ISSMC: Partner

Coordinator: Prof. Alessandro Bottaro (Direttore del Dipartimento DICCA, Università di Genova)

Consortium: Politecnico di Bari (Prof.ssa Stefania Cherubini), Università degli studi di Genova (Prof. Alessandro Bottaro), CNR-ISSMC (Dott.ssa Mariarosa Raimondo)

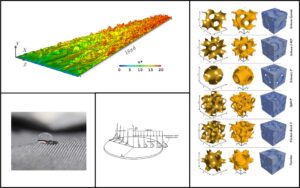

SLIPS will leverage the complementary instruments and expertise of the three units to advance the understanding of the wall friction behavior of Slippery, Lubricant-Infused Porous Surfaces (SLIPS). There are no clear guidelines for optimizing SLIPS for a given application, neither in terms of the microstructure/material of the porous matrix nor in terms of the properties of the most suitable lubricant. Additionally, SLIPS face challenges related to the lack of persistence of the “slip” effect over time. Therefore, a multidisciplinary effort has been conceived to address these aspects.

Objectives:

- Study the microscopic problem in the vicinity of SLIPS, taking into account capillary effects, to obtain high-order slip boundary conditions.

- Use advanced manufacturing technologies to develop hierarchically microstructured solid-liquid interfaces.

- Produce SLIPS through an innovative technique that couples lubricant-imbibed porogens, such as ceramic-based porous scaffolds (e.g., alumina, aluminosilicates), zeolite powders, with more conventional materials like PDMS.

- Test the developed materials through both electrochemical impedance and rheological measurements to evaluate the effectiveness in reducing friction and the durability of the coatings.

- Analyze the modal and non-modal stability of the flow over SLIPS coatings.

- Conduct direct numerical simulations of turbulent motion. The use of intelligently designed SLIPS should significantly influence the onset and development of small perturbations, as well as the developed turbulent flow, offering significant potential for friction reduction.

The multidisciplinary approach pursued aims to develop new and effective strategies for the design and production of durable SLIPS coatings over time.

Activity funded by the European Union Next Generation EU, via PRIN PNRR 2022 grant, project code P2022CZ5KZ