This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

DIGIMAN

Digitizing solutions for companies in the manufactoring sector

Principal Investigator: Carlo Baldisserri

Involved personnel: Carmen Galassi, Claudio Capiani, Davide Gardini, Alex Sangiorgi, Emanuele Migliori, Simone Casadio, Simone Fabbri

Administrative management & financial reporting: Laura Mengozzi

- Starting date: 15/04/2019

- Duration: 24 mesi

- Total funding: 799 962 €

- Call: POR-FESR Emilia Romagna 2014-2020

- Coordinator: Paolo Albertelli (Politecnico di Milano)

- Consortium: MUSP (Piacenza), CNR-ISTEC (Faenza), MIST-ER

- Involved companies: MCM SpA, Mandelli Sistemi S.p.A., Jobs S.p.A., Marposs S.p.A., SCM s.r.l., Poggipolini s.r.l.

- Official website: https://www.digiman.tech/index.php/

Machining is the main means whereby a range of raw materials – typically alloys and plastics – are shaped into a wide range of machinery parts by means of removing excess material by some sort of cutting action. Use of cutting bits made from very hard composite materials have come into use, largely superseding the use of earlier carbon and HSS steel, decidedly improving the cutting performance.

Cutting is a very complex process, during which large mechanical stresses develop at the tool/workpiece interface. Stresses critically depend on many factors, such as type of material being cut and that of the tool bit and means of lubrication and cooling. Tool bit wear is accompanied by unwanted side effects such as blunting of the cutting edge, galling, and increasing vibrations amplitude, which result in a coarser cutting action. This gradually worsens tooling performance, degrading surface finish and dimensional precision, also affecting key properties of the finished part such as surface hardness and wear resistance.

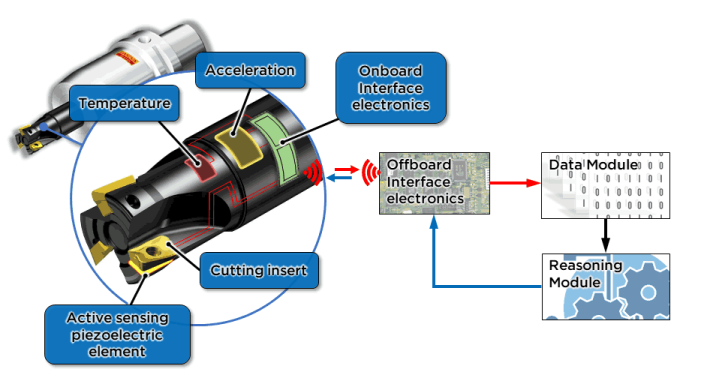

By suitably coupling sensors in the vicinity of the cutting area, so that mechanical stresses can be converted into an electric signal, it is possible to achieve real-time monitoring of the cutting process. Cutting performance degradation will cause some features of the signal to change over time, allowing informed decisions to be made as to the opportunity of changing or refreshing the tool bit cutting edge, or varying the cutting process parameters.

CNR-ISTEC’s role in the DIGIMAN industrial research project is that of designing and providing sturdy and sensitive piezoelectric ceramic sensors directly coupled to the tool bit, able to withstand the large stresses that the latter endures and transmits to the sensor, the latter being expected to output a strong voltage signal to be used in the digital monitoring and active control of the cutting process.