This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

FIREMAT

Fire resistant materials & composites

Principal Investigator: Valentina Medri

Personnel involved: Annalisa Natali Murri, Elettra Papa, Elena Landi, Francesco Miccio, Luca Zoli, Ylea Vlamidis

Starting date: 05/07/2019

Duration: 24 months

Total funding: 800.000 €

Action: POR-FESR Emilia Romagna 2014/2020 – ASSE 1 – Research and Innovation, Action 1.2.2

Project Coordinator: Claudio Mingazzini (ENEA-TEMAF)

Consortium: ENEA-TEMAF (Faenza, RA), CNR-ISTEC, CertiMaC Soc. Cons. a r.l. (Faenza, RA), Consorzio MUSP (Piacenza), Romagna Tech S.c.p.a. (Faenza, RA)

Involved companies: RI-BA Composites S.r.l. (Faenza, RA), Curti Costruzioni Meccaniche SpA (Castel Bolognese, RA), Aliva S.r.l. (San Mauro Pascoli, FC), Tampieri Energie S.r.l. (Faenza, RA).

Official website: www.firemat.it

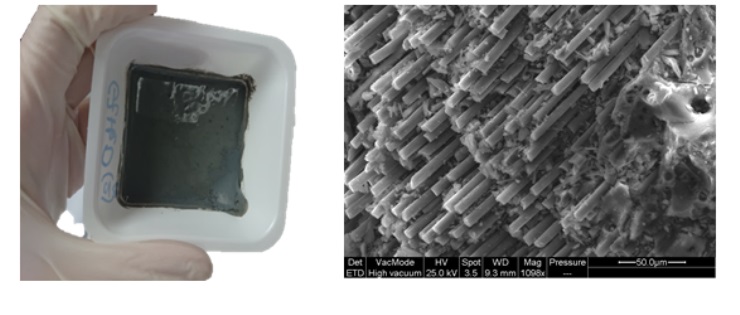

FireMat develops low-density thermostructural materials for lightening and increasing safety, specifically long and short fiber reinforced composites, for high temperature and fire protection. FireMat is born from the awareness that the main technological limit for the application of polymeric composites (PMC) is the insufficient temperature resistance, while for ceramic matrix composites (CMC) they are the excessive costs, times and productive complexity.

The project starts from a solid base, which includes a multi-year partnership activity that stands out above all for the development of pilot lines of industrial size. These lines can be used both to develop semi-finished products and to produce real-scale demonstrators.

Expected results: realization and implementation on a real scale of two macro-types of heat-resistant materials. The first will concern fire-resistant composites with a preceramic polymeric matrix reinforced with basalt fiber; the second, of which CNR-ISTEC is responsible, aims at thermal barriers, with working temperatures up to 800 °C (depending on the composition) thanks to the ultra-refractory additives.

The TRL 4/5 already acquired will be implemented at TRL 6 by improving the formulations, ad hoc pilot lines and full-scale prototypes.