Tubular furnaces

Supervisors: Alex Sangiorgi, Luca Zoli

Tubular furnaces are electric heating devices mainly used to carry out synthesis and purification of compounds/products with an inorganic matrix, such as ceramics. Their particular design makes it possible to quickly reach high temperatures in a well localized area of the heating chamber, thus guaranteeing an excellent heating homogeneity. Another important aspect is the modularity of this class of furnaces, in fact it is possible to use different materials tubes, including metal, quartz and ceramic, depending on what you will treat thermally.

In ISTEC, there are two tubular furnaces mainly used in one case for heat treatments in a reducing atmosphere and in the other one, for the production of composites by pyrolysis of organic and inorganic polymers and finally, for non-oxidic powders synthesis.

RHTH 120-600/16, Nabertherm (Germania)

- Maximum temperature 1600°C;

- Maximum heating rate 200°C/h;

- Tubular chamber made of ceramic (alumina);

- Heating atmosphere based on pure air or Ar/H2 mix.

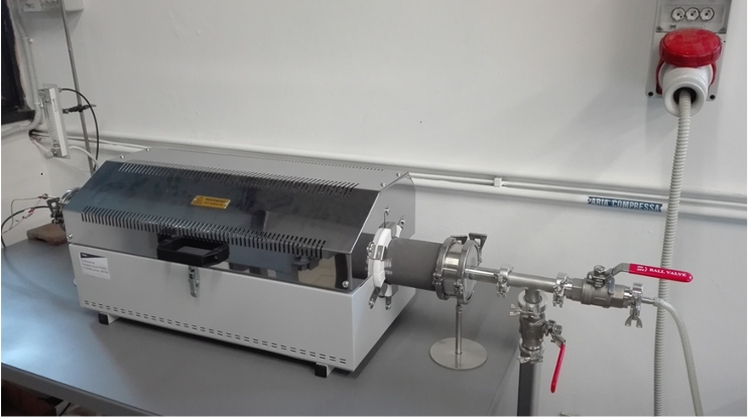

HST 12/600 220, Carbolite Gero (Germany)

- Maximum temperature 1200°C;

- Maximum heating rate 20°C/min;

- Tubular chamber made of steel;

- Heating atmosphere based on Argon, Nitrogen or vacuum.