This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Micronization system

Supervisors: Monica Sandri, Elisabetta Campodoni

A micronization system is generally used to reduce the particle size of a product. The working principle is based upon a high-pressure gas, used to accelerate the product in the milling chamber and obtain particle-particle collisions with product fragmentation. Several parameters can influence the size reduction such as chemical and physical properties of product, nozzles line pressure, product feed rate into the milling chamber, process temperature and gas relative humidity.

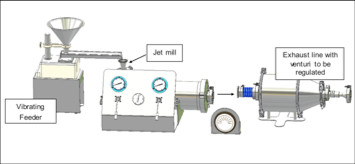

PILOTMILL-2 micronization system:

The equipment is designed to use air or nitrogen as a process gas. It is laboratory size micronization equipment that allows particle size reduction down to micron size when required, on quantities of material from 0.5 g to 3000 g.

This micronization unit is composed of the following elements:

- JetMill base unit composed of: upper plate fitted with injection line; classifier and top-discharge configuration; lower plate fitted with nozzles support; gas expansion nozzles, product injection line;

- Product transport line;

- Large batch set (100 g- 500 g) composed of a filtering housing made in AISI316L stainless steel, complete with support and a filtering sock in antistatic PE acting also as a product container;

- Small batch set (1 g – 50 g) composed of a filtering housing made in AISI316L stainless steel, complete with support and a filtering sock in antistatic PE acting also as a product container;

- Vibrating feeder;

- Control manifold composed of manual ball valves and pressure gauges for gas grinding line and gas injection line and a thermometer (-40+60 °C) for process gas temperature;

- Exhaust HEPA filter: in order to prevent extra small particles to be dispersed.

Technical details:

- Completely manufactured in AISI316L stainless steel in all product contact parts. The other components are in AISI304 stainless steel;

- Maximum working pressure: 12 bar;

- Gas comsuption: 11Nm3/h at 7 bar or 18 Nm3/h at 12 bar;

- Productivity: 0.05 – 1 kg/h;

- Temperature operating:ambient temperature from -10 °C to +35 °C;

- Power supply: 230 V;

- Equipment weight: 60 kg;

- Noise issued 97 dbA.