This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Microwave oven

Supervisor: Magda Blosi

The microwave oven is a specific tool for chemical synthesis and exploited for the synthesis of colloidal nanosuspensions as it allows a quick reaching of the desired temperature and a high thermal homogeneity inside the synthesis flask.

Principle of operation

The instrument, equipped with temperature control, cavity to house coolant and magnetic stirring, works at a frequency of 2.45 GHz. The maximum power that can be supplied is 1000 W, and is generated by two lateral magnetrons, with a capacity of 800 W each. The magnetron is also equipped with a protection against excess energy deriving from reflected microwaves. The maximum temperature that can be reached is 300°C.

The system is multimodal and has a magnetic device capable of homogenizing the power throughout the cavity. Power delivery can be either continuous over time or pulsed, that is, interspersed with zero power breaks.

Main characteristics

The oven consists of a structure entirely in stainless steel and a hatch in steel with a glass viewing window and the cavity is completely covered in teflon.The instrument is equipped with an EasyCONTROL software that allows you to set the heating ramps and the permanence in temperature, manage automatically and in real time the power level emitted and reproduce in a systematic and constant way the reactions developed and memorized, also allowing the acquisition of all operating and process parameters.The temperature is controlled by means of an optical fiber inserted in the reaction environment and coated with a teflon support.

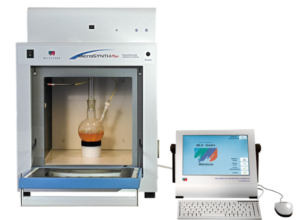

Milestone Microsynth Plus

- Gas sensor: capable of detecting the possible presence of organic vapours in the work cavity, with instantaneous interruption of the microwave emission if the maximum limit is exceeded.

- Processable volumes: 50 – 700 mL.

- Pressure control device: hydrothermal syntheses can be carried out at a maximum pressure of 30 bar.

- Processable volumes for hydrothermal syntheses: max 150 mL.

- The software allows you to set the following parameters: final temperature; time to reach the final temperature; maximum power output.