This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Smart Surfaces

The demonstrator is the result of a collaboration between CNR-ISTEC and CNR-IMAMOTER, which took care of the design and assembly. The date of implementation and first application dates back to July 2016, while his first exhibition was at the BIMU fair in Milan (3-5 October 2016).

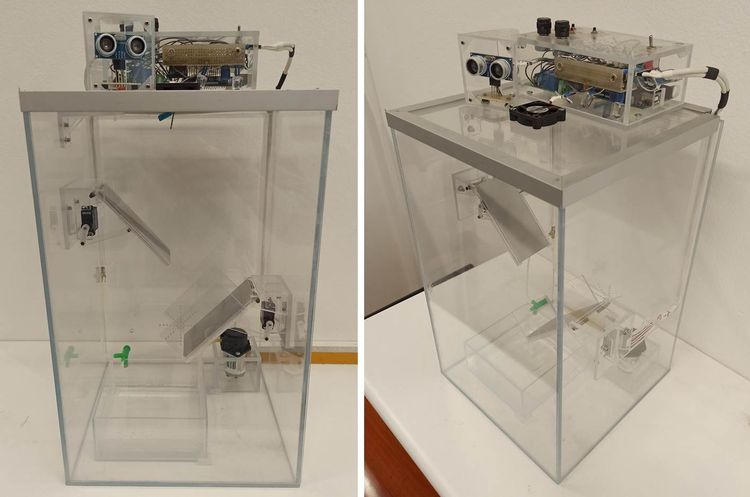

The demonstrator is designed to highlight the superhydrophobic behavior of nanostructured hybrid coatings, designed and applied in ISTEC on metal supports. The demonstrator includes a water drop dispensing system, connected to an electronic circuit that regulates the flow rate and frequency. Two metal substrates are located on two plexiglass supports equipped with analog controllers that allow both manual and automated tilting. The upper substrate bears the superhydrophobic coating on its surface while the bottom one is an untreated surface. The cage also includes a system for water circulation. Placing the superhydrophobic surface in the upper support and the uncoated substrate in the lower one is possible to see their different interaction with water. The drop, impacting the functionalized surface, will have no interaction with it, sliding very rapidly on it and then subsequently striking the untreated underlying surface, on which it will stick due to the high adhesion force between the bare metal and the liquid. The treatments responsible for obtaining superhydrophobicity present an hybrid, organic/inorganic nature, with an inner part made of a nanostructured ceramic layer and an external organic layer, which decrease the surface energy in order to confer an outstanding repellency to water and to other types of liquids with lower surface tension. On the bottom of the case there is a tank connected to the hydraulic pump which allows water to be recycled, thus avoiding continuous refill. To avoid excess humidity in the case, which would lead to fogging of the plexiglass walls and damage to the electronic components, an internal fan has been inserted, connected to a humidity sensor, which activates a forced recirculation of air from the outside.

A lever selector discriminates the operation of the machine between manual or automatic. An ultrasonic sensor allows the automatic start of both pump and tilting system for one complete cycle which includes the movement of the plexiglass supports at all the angles programmed on the software.

Weight: around 2 kg

Dimensions: 23cmx23cmx36cm